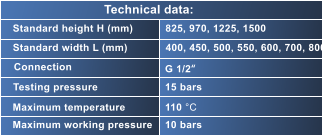

Технички информации:

Transport and storage:

Installment and usage:

Production proces

Materijal

- Steel qadrant profile 25*25*2 mm

- Steel oval profile 30*15*1,2 mm

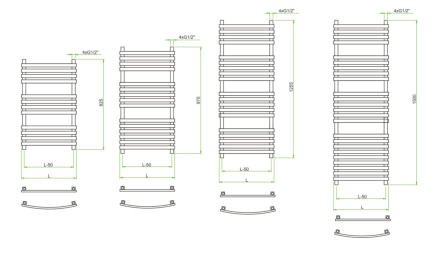

- Connecting from one side k = 1.0

- Diagonal connecting k = 1.011

- Connecting from bottom k = 0.959

NO2-P 1500/450

NO1-P 1250/500

NO2-S 970/550

NO1-P 970/600

Termostil DOOEL

2314, Blatec, Vinica

R. Makedonija

tel. +389 (0)71 331 066

by Termostil team

The Tubular radiators TERMOSTIL are made from steel jointed pipes profiles.-

oval profile 30*15*1.2 mm, quadrant profile 25*25*2 mm. The welding is done in

three fazes depending on which operation is in faze: MIG-MAG, TIG and HF

(high frequency welding). The hole welding cycle is done by CNC machines.

The radiators are made with four standard G ½ connections.

The general heating medium used is water, but you can also use other anti-frost liquids.

As a treatment before the electrostatic painting is the electrochemical degreasing,

electrochemical phosphate and Passivation. The plastification is done by electrostatic

applying of powder paint which is dry - heated on 180°. The testing medium used is

compressed air at 15 bars.

The Radiators TERMOSTIL come packed in a cardboard box together with all the

required Accessory for instalment - plastic console, wall - rivets, screws, mechanical

valve, stops and manual for instalment.

The radiator should be stored in a dry and ventilated place.

- Instalment must be according to the adequate standards and regulations.

- The heating fluid must be softened in according to the regulation for hardness of

working fluids.

- Emptying the system is not recommended to avoid rust problems.

- Installment must done by a qualified and trained worker.

With every radiator come 3 or 4 plastic brackets

with which it is safely attached to the surface.

The degree ofefficiency depends

on the way the radiator is

connected